Brilliantly British: Daily Express launches new campaign

Cumbria Crystal

It takes an average of 15 years of full-time glassblowing before a glassmith can practise their skill at Cumbria Crystal, the last British producer of luxury hand-blown and hand-cut lead crystal tableware. “I use the analogy of the lead violinist in the National Symphony Orchestra,” says chief executive officer Chris Blade.

“The musician must put in their 10,000-plus hours before being considered for inclusion. We are no different.”

Dating back 2,000 years, glassblowing is the process of forming molten glass by an artisan blowing air through a special pipe.

Cumbria Crystal, located in Ulverston in the Lake District, produces glassware with a 24 per cent lead content, producing a higher shine and sparkle than other glasses.

“The techniques we use today are almost exactly those used by the Romans,” says Chris. “The differences are in the purity of the glass and materials, and refined processing. We also use gas furnaces instead of wood or coal.”

So prized are Cumbria Crystal’s collections that they are the official glassware of several royal families and the British embassies. The company’s tumblers, glasses, jugs and vases featured in Downton Abbey, while a double old-fashioned whiskey

tumbler from the Grasmere collection was sipped by Daniel Craig in Casino Royale.

Today, bespoke glass-making is a fraction of the size it was during the Industrial Revolution, and jobs are few.

Cumbria Crystal is keeping the tradition alive, counting four highly-skilled glass blowers among its 23 employees.

“We’re immensely proud we can still do this,” says Chris. “However, I live more in fear of it than the pride of it as on my shoulders rests the survival of one of Britain’s great heritage industries. “If we were to disappear, so would luxury crystal making in this country.”

A single wine glass takes between 10 days and two weeks to complete.

“Only 100 pieces are produced a day and half of what is produced is rejected – but recycled – for quality purposes.

“The origins of everything we do comes from human ingenuity and craftsmanship,” says Chris. “We’re creating heritage pieces that should last for thousands of years. They’re the antiques of the future.”

cumbriacrystal.com

Dualit

A coveted kitchen icon, the Dualit Classic Toaster design remains largely unchanged since its conception in 1952.

Available in 20 colours, each model is made from die-cast aluminium and durable stainless steel, and is hand-assembled from start to finish by one craftsperson at Dualit’s factory in Crawley, West Sussex.

The end castings are hand sprayed by Brian, who has worked for the company for a quarter of a century, and if you removed them you would probably see his handprints.

“Our assemblers are integral to the product’s creation and are immensely important to the Dualit family so giving them individual recognition of their skills on each toaster is just one small way we can demonstrate this,” says Alex Gort-Barten, Dualit director.

Dualit.com

Dartington Crystal

Based in Torrington in north Devon, Dartington Crystal remains the only large-scale glass maker in the UK. Each quality piece is made using traditional mouth-blowing techniques. Drinkers can select designs from port glasses to tankards, while glass vases, candle holders, clocks and bowls are also available.

Neil Hughes, managing director, says: “With people spending so much time indoors and with family, we offer a great choice for gift-giving and home enhancement. Our customers have the option to add personalised engraved text to any piece.”

dartington.co.uk – use code EXPRESS20 at dartington.co.uk for a 20 per cent discount. Valid until December 20, the code cannot be used in conjunction with any other offer.

Sinclair Harding (UK) Ltd

Founded by Bill Sinclair and Mike Harding in 1967, Sinclair Harding makes some of the finest clocks in the world inspired by the famous British makers of yesteryear.

Almost every component of every intricate mechanism is painstakingly assembled in a Yorkshire workshop by current Sinclair Harding custodian Bob Bray.

Using a combination of modern technology and traditional processes, he fashions parts as diverse as a miniature chain to hand-tuned bells.

Age-old skills are practised daily – French polished wood, hand-silvered dials, and flame-blued screws to name a few – producing clocks with soul and character.

Up to 70 designs are made per year, supplied to retailers and customers around the world. Bob says: “The whole clock making process gives me a genuine buzz – the initial enquiry, tailoring each clock, seeing it take shape, witnessing the first tick and seeing the smile on the customer’s face when I open it in their home makes me a lucky man.”

clockmakers.com

Dualit toasters are hand-assembled by one person from start to finish in a West Sussex factory (Image: Barney Warner Photography)

Emma Bridgewater

Her country-inspired teapots, plates and mugs are the stars of many kitchen dressers and tables.

The company was founded by Emma Rice, née Bridgewater, in 1985 after she struggled to find a special cup and saucer for her mother’s birthday. All the available options seemed “too formal or clunky”, she says.

“There was a gap in the market for pottery that was beautiful and practical – pottery that reflected the relaxed, colourful, mismatched home I’d grown up in,” she says.

Emma’s designs always feature “what we would like to have in our own kitchen” and are from real-life inspirations. “Our Rise & Shine – Hens collection was inspired by real bantams my mother kept when I was a child.

“A particularly generous crop of tomatoes a few years ago inspired a bowl covered in illustrated tomatoes.”

Each item uses cream-coloured earthenware, a traditional Staffordshire non-vitreous pottery made in the company’s Stoke-on-Trent factory where 300 employees work. Production is still mainly done by hand and every piece is hand-decorated so no two pieces are ever the same.

emmabridgewater.co.uk

Made to Last

Focusing on quality furniture and lighting, Made to Last encourages customers to think about sustainability. Clear guarantees are highlighted at the point of purchase so the consumer understands the longevity and value of each purchased product.

Made to Last co-founder Joel Chudleigh says: “Buying through Made to Last ensures you will be purchasing products that last well. In most cases, you will also be supporting the British manufacturing industry too.”

Lighting includes floor and table lamps, wall and ceiling lights, spotlights and chandeliers, see left.Storage facilities range from chests of drawers and ottomans to bookcases and wardrobes.

made-to-last.co.uk – use code DAILYEXP10 for a 10 per cent discount until December 31.

Emma Bridgewater’s country-inspired homeware is famous around the world (Image: Emma Bridgewater)

Putnams

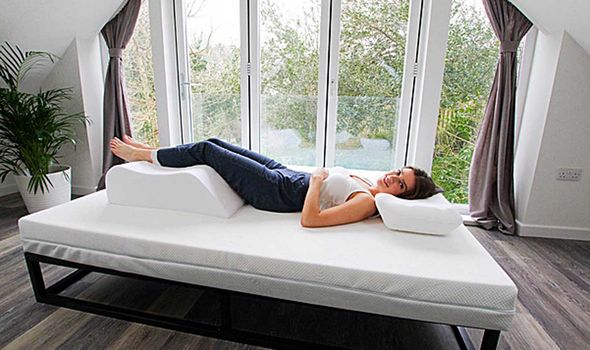

A second-generation, family-run manufacturing company based in Devon, Putnams provides products – including pillows, bed wedges, kneeling chairs and pressure cushions – to relieve a wide range of health conditions.

Co-director Bubbles Putnam, who runs operations with her brother Hedley, says: “We make our products by hand in the factory.

“Every pillowcase, cover and upholstered kneeling chair is cut, sewn and upholstered by hand and our lengthy product guarantees reflect this.”

putnams.co.uk – use code EXPRESS for a 10 per cent discount

Putnams’ products include bed wedges, plus kneeling chairs and pressure cushions (Image: Putnam Health)

Perkins & Morley

Female designers Jill Perkins, 74, and Jan Morley, 59, launched their homeware, stationery and lifestyle brand in 2010.

They met 30 years ago as graphic design students after bonding over a shared passion for art and design and created tableware for other businesses.

But when Jan drew an adorable otter, it inspired them to set up Perkins & Morley. That otter now forms part of theirbest-selling range of quirky greetings cards and giftware.

Both women come up with their ideas in the great outdoors – Jan regularly walks among the valleys and fells of Cumbria with a camera, while Jill sketches and paints in Devon, surrounded by beautiful coastlines.

Their products include coasters, cushions, prints, aprons, clocks and chalkboards, all made in the UK.

perkinsandmorley.com

Revival Beds

These handcrafted solid wooden beds have been made in Nottinghamshire since 1983. The idea came about after two cabinet makers teamed up to restore antique furniture and found they were unable to source traditional bed designs suited to the modern-day customer’s preference for wider frames.

Timber is sourced from sustainably managed forests using the finest cuts chosen for their strength and character.

“We either use European oak or solid pine, depending on the customer’s requirements,” says Revival Beds director Adrian Leary. “The leather we use is manufactured in Scotland and we also supply mattresses that are made in Yorkshire and bedding in Lancashire.”

Each bed takes an average eight weeks to make. Adrian hopes more people will invest in British products in the future.

“If so it will mean we can continue to upskill our employees and invest in their development and the future of the UK economy,” he says.

revivalbeds.co.uk – a 7.5 per cent discount is available to readers who quote Express 20 over the phone.

Revival Beds are made in Nottinghamshire (Image: Revival Beds)

Feature Lighting

Founder Jacqui Jones is a design graduate and former glassblower with 25 years’ experience in the lighting industry who bought a lampshade factory and started her own brand.

Feature Lighting manufactured for other brands prior to Covid-19 but has since launched its own online shop selling original designs.

Jacqui says: “We are based in Lancashire and like using Lancashire-made fabrics and wallpapers to cover our lampshades, although we are not limited to them.

We custom make bespoke lampshades, made to measure and can use customers’ own materials in shapes and sizes not found on the high street.”

feature-lighting.co.uk

Perrin & Rowe

When good friends and repair enthusiasts Bob Perrin and Greg Rowe began helping small companies manufacture hard-to-make components 40 years ago, they realised there was a real need for their engineering skills.

Decades on from that first tinyfactory in London’s East End, Perrin & Rowe has become a globally known kitchen and bathroom fittings service.

Every product range is created in small batches with care, using high quality raw materials. Brassware is cast by hand in Wolverhampton, while a small and highly skilled team produces chinaware and product moulds in Tamworth.

Every tap, lever or sink has a range of styles and finishes and is designed, engineered and made in the UK.

David Cole, marketing manager, says: “British brands excel in combining traditional craftsmanship with modern techniques. Perrin & Rowe epitomise this philosophy, manufacturing taps and sanitaryware in the UK using a highly skilled workforce, aided by state-of-the-art technology.”

perrinandrowe.co.uk

Samuel Groves has made kitchenware since 1817 (Image: Samuel Groves )

Samuel Groves

Samuel Groves began making kitchenware in 1817 when it produced brass candlesticks before branching out into electro-plated teapots and trays.

Following huge expansion during the Second World War, it introduced the popular Mermaid bakeware brand into its range in the 1950s, which it still manufactures today.

Current bestsellers include its sturdy and stylish set of stainless-steel tri-ply pans.

Employees continue to adopt traditional techniques from metal cutting and welding to metal spinning, presswork and injection moulding to create the highest-quality products with a hand-finished guarantee.

The firm was rescued by the family-owned, Birmingham-based U Group in 2016.

Managing director Lee McDonagh says: “Samuel Groves cookware not only uses recycled boxes but has also replaced its plastic packaging by using hessian bags which can be then used for product storage, or vegetables.

“Furthermore, they will biodegrade at the end of their life.”

samuelgroves.com

Hettie

Hettie’s country-inspired accessories come in a range of earthy colours to add depth

to your home. Its luxurious throws carry the trusted Woolmark industry certification logo, guaranteeing the highest possible quality, and its soft cushions are crafted using wool woven from the same British mill since 1837.

Collections inspired by riverside and woodland locations are made with a “slow fashion” approach to ensure sustainability and good-quality garments are produced for every customer. Bags, dog coats and collars, and lifestyle accessories are also available.

Sian Reekie of Hettie says: “We celebrate the simple things in life and family values.

“People need to think a little bit more about the wasteful things that they do and the amount they throw away. There has never been a better time to buy British.”

hettie.co.uk – use code BRITEX20 for a 20 per cent discount on all woollen products

Simplex Kettles by Newey & Bloomer

Newey & Bloomer, founded in 1850, is the British manufacturer of the iconic whistling, solid copper Simplex Kettle range.

“All our copper kettles are handmade in Birmingham just as they have been since 1903, says Lee Sheppard, Newey & Bloomer’s managing director.

“The longevity and timelessness of these kettles mean this investment is something that will stay in your kitchen for generations.”

Each gleaming kettle has an attractive aesthetic pairing of a solid base with brassed curved handles and a ‘bird’s mouth’ spout.

neweybloomer.co.uk – use code DEX20 until December 31, 2020, for a 20 per cent discount

Hettie sells a range of beautiful woollen throws and cushions (Image: Hettie)

Henry vacuum

Independently rated the country’s most reliable vacuum brand, Henry is a British icon.

More than 12 million models sporting the famous smiling face have rolled off the production line since 1981, each one designed, engineered and made on home soil.

Henry was created by Chris Duncan in 1968 and was developed under his company Numatic International into the canister-shaped vacuum cleaner it is today.

Henry remains the UK’s best-selling cylinder vacuum cleaner, with one built every 30 seconds at the factory in Chard, Somerset. New technology and features may have been added over the years, but the much-loved design has not altered since 1981.

Andrew Ernill, head of marketing at Henry, says: “People love Henry because he cleans up everything and never breaks down.

He just goes on and on. Henry has seen some changes over the years, but the core of Henry – great cleaning performance and his famous smile – has remained unchanged.”

myhenry.co.uk

Silentnight

Britain’s biggest bed manufacturer is also the nation’s most trusted name when it comes to getting a good night’s sleep,

says managing director Neil Anderson. “Exceptional quality and service is really at the heart of the business – it’s lived and breathed by all,” he says.

“Our mattresses go through rigorous testing in our independent, in-house testing lab, which is also one of the very few SATRA-accredited labs in the UK. So when customers buy a Silentnight product they can trust it to deliver on safety, durability and comfort.”

Silentnight has manufactured sleep products from its factory in the Lancashire countryside since 1946. The heritage brand has also won awards, including a Which? Best Buy, for its commitment to sustainability through its Eco Comfort range.

Each mattress uses fibres manufactured from up to 850 recycled plastic bottles, which are then crushed and spun into a soft fibre.

silentnight.co.uk

Express Bi-Folding Doors have featured on Channel 4’s Grand Designs (Image: Express Bi-Folding Doors)

Spode

This year marks the 250th anniversary of luxury tableware and pottery firm Spode. Founded by Josiah Spode in 1770, the brand’s first factory was

in Stoke-on-Trent, regarded then as Britain’s industrial heartland and now as the world capital of ceramics. Spode’s Blue Italian design is one of its most enduring ranges, dating back to 1816.

A new limited edition, Black Italian – the iconic design but in monochrome colours – has been launched to celebrate the special birthday and features mugs, espresso cups and gifts sets with brushed gold spoons.

Spode brand manager Sara Dickenson says: “Blue Italian was immediately popular and remains one of the brand’s most admired and recognised collections in the portfolio.

Over its 200-year life, hundreds of different pieces have been designed and the majority is manufactured in Stoke-on-Trent to this day.”

spode.co.uk

Made Below

Specialising in footstools, benches and ottomans, Made Below is the brainchild of Charlotte Cochrane whose background is in upholstery. She wanted to create long-

lasting pieces to prevent wasteful updates or new purchases. “Ultimately I wanted to reject mass-produced furniture that lacks quality and individuality and create something ‘hyper-local’ made by human hands that care,” she says.

Each small-batch furniture collection uses fabric from one of England’s oldest mills, wood from local FSC suppliers, and legs hand-turned in Manchester from British-grown wood.

uses fabric from one of England’s oldest mills, wood from local FSC suppliers, and legs hand-turned in Manchester from British-grown wood.

madebelow.co.uk